Data acquisition systems, shortened to DAS or DAQ, are systems designed to convert analog waveforms into digital values, so that they can be used for processing. In other words, they take abstract data and record it in such a way that humans can interpret it and use it. Read More…

CAS DataLoggers is a B-2-B distributor of data loggers and data acquisition systems required by industries in need of data collection, monitoring and control of environmental, production, process and quality control variables. From more than 18 manufacturers, we offer high-speed, high-accuracy data acquisition systems that can record temperature, force/strain, flow, voltage, vibration and more....

At Oil-Air Products, we are dedicated to delivering advanced hydraulic and pneumatic solutions that help our customers achieve greater control, efficiency, and performance in their systems. A key part of that mission is our expertise in Data Acquisition Systems, which allow us to capture, monitor, and analyze critical information from fluid power applications.

When it comes to data acquisition and control for the distribution and manufacturing industries, we can help. We are systems integrators who understand data acquisition software and data recorder functions-inventory control (raw material, finished goods), tracking (print job, work order, tool room) and more.

More Data Acquisition System Companies

Applications

Data acquisition systems (DAS or DAQ) are the backbone of modern measurement, monitoring, and process control, providing seamless conversion of analog signals into digital data for real-time analysis and actionable insights. By digitizing sensor outputs, these systems enable accurate and efficient data recording, interpretation, and automation across a vast array of industries.

Key industries leveraging data acquisition technology include:

- Aerospace and Defense: For flight data acquisition, avionics testing, and vibration monitoring during aircraft development and maintenance.

- Medical and Life Sciences: In clinical trials, patient monitoring, and biomedical research, DAQ systems capture physiological signals like ECG, EEG, and vital signs with high precision.

- Environmental and Water Management: For continuous monitoring of wastewater toxicity, air quality, and environmental compliance, enabling timely responses to regulatory thresholds.

- Industrial Manufacturing and Automation: DAQ systems empower factories to track and optimize parameters such as temperature, pressure, voltage, and current, supporting predictive maintenance and process optimization.

- Automotive and Transportation: Used in performance testing, crash analysis, and emissions monitoring, ensuring vehicles meet stringent safety and environmental standards.

Operators utilize advanced DAQ software and data acquisition hardware for high-resolution measurement, process monitoring, and product testing. These tools provide critical data input for process control adjustments, root cause analysis, and quality assurance. Data parameters commonly monitored include, but are not limited to, gas pressure, voltage, current, temperature, acceleration, and force.

Typical use cases and applications include:

- Flight data acquisition and telemetry for aerospace R&D and compliance

- Structural dynamics and fatigue testing in civil and mechanical engineering

- PC-based and networked data collection for laboratory and field research

- Web-based, centralized data acquisition for remote site monitoring (e.g., environmental sensors in distributed locations)

- Clinical trial data management and electronic data capture in healthcare

- Process monitoring and SCADA integration in industrial automation

- Product troubleshooting and failure analysis in manufacturing

Are you looking for:

- Data acquisition solutions for high-speed or high-channel-count applications?

- Industry-specific DAQ systems tailored for environmental, medical, or automotive use?

- Software integration with your existing process control infrastructure?

- Portable or distributed DAQ systems for field studies or remote monitoring?

Explore our Data Acquisition System Companies directory for specialized suppliers and tailored guidance.

History

The evolution of data acquisition system (DAS or DAQ) manufacturing traces a remarkable path from simple mechanical devices to today’s highly integrated, digital, and IoT-ready systems. This transformation has been shaped by advancements in electronics, computing, sensor technology, and the escalating needs of science, industry, and defense. Understanding this history not only highlights technological progress but also helps buyers appreciate the capabilities and limitations of current DAQ solutions.

Early 20th Century: Mechanical Roots

Initial data acquisition was entirely manual. Technicians recorded process variables—temperature, pressure, and flow—on paper charts using mechanical chart recorders. These analog tools were labor-intensive, prone to human error, and restricted in sampling speed and data longevity.

Mid-20th Century: Analog Instruments Dominate

By the 1950s and ‘60s, innovations like oscillographic and strip chart recorders (notably from Brush/Gould) improved data logging accuracy and speed. These analog DAQ solutions became essential in manufacturing, research, and government projects (including NASA’s space missions). Despite their reliability, analog systems were limited by their bulk, slow operation, and inability to support complex, multivariate analysis.

1960s: Digital Dawn

Computing began to intersect with data acquisition. IBM’s 7700 and 1800 series introduced electronic analog-to-digital conversion, paving the way for digital DAQ. These systems, however, were large, costly, and used mainly in military, aerospace, and government laboratories due to their complexity and price.

1970s: PC Revolution and Democratization

The rise of affordable, general-purpose computers—like S-100 systems—enabled broader DAQ access. Tecmar/Scientific Solutions pioneered plug-in data acquisition cards, making it possible for small businesses and academic researchers to implement high-speed, multi-channel data collection without the overhead of mainframes.

1980s: Digital Integration and Miniaturization

The shift to digital continued, with DAQ hardware adopting microprocessors, digital I/O, and multifunction plug-in cards compatible with ISA or PCI buses. Leading brands included Keithley, Data Translation, and National Instruments. This era saw the introduction of thermal array printheads, high-speed memory, and modular system designs that set the stage for today’s scalable, flexible DAQ architectures.

1990s: PC-Based DAQ and Software Innovation

With the proliferation of Windows PCs, software-centric DAQ became mainstream. National Instruments’ LabVIEW and similar graphical programming environments reduced development complexity and enabled powerful data visualization, processing, and automation. Modular rack systems like CAMAC and VME allowed users to build customized DAQ setups with plug-and-play functionality.

2000s: Networking and Industrial IoT

The DAQ industry embraced Ethernet, USB, and WiFi connectivity, supporting remote and distributed data collection. Industrial Internet of Things (IIoT) applications required rugged, real-time, and high-accuracy DAQ hardware, driving adoption of advanced protocols (CAN, Modbus, MQTT) and centralized control via SCADA systems. Modular DAQ platforms from Dataforth, Keysight, and Siemens offered scalable, cloud-ready solutions for factory automation, energy monitoring, and predictive maintenance.

2010s–Present: Smart, Connected, and Sustainable DAQ

Contemporary DAQ systems feature wireless communication (Bluetooth, WiFi), ultra-low-noise electronics, simultaneous sampling, and seamless integration with cloud analytics. Companies like Dewesoft, UEI, Comptek, Averna, and Sciotex focus on rugged, distributed architectures for harsh environments and remote sensing. Emphasis on sustainability has produced low-power, battery-operated DAQ modules for environmental and geotechnical applications. The global industrial DAQ market continues to expand, driven by the demand for real-time, data-driven decision-making, predictive analytics, and regulatory compliance.

Critical Considerations

While digital DAQ systems offer unmatched power and flexibility, they introduce complexity—cybersecurity, software dependencies, and market consolidation risk stifling niche innovation. Buyers must weigh simplicity, reliability, and long-term support when selecting DAQ solutions for specialized or mission-critical applications.

Want to learn more about the evolution of DAQ technology? Search “history of data acquisition systems,” “transition from analog to digital DAQ,” or “impact of IIoT on industrial data acquisition” for in-depth articles and whitepapers.

How It Works

A data acquisition system collects, conditions, digitizes, and processes physical or electrical signals, transforming them into actionable digital data. This process underpins everything from environmental monitoring to industrial automation, and is fundamental to Industry 4.0, smart manufacturing, and advanced research.

Key data acquisition steps:

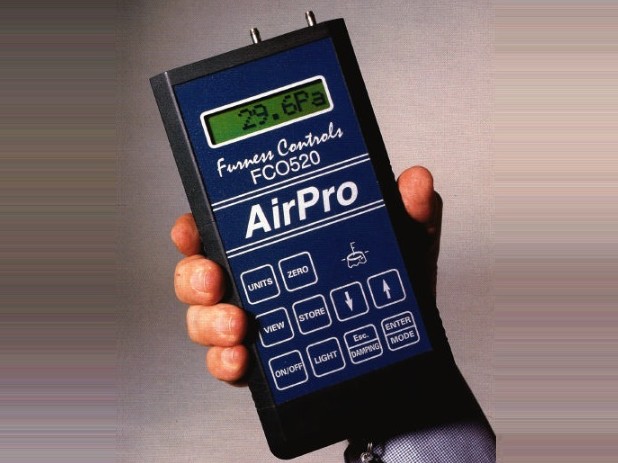

- Data Collection: Sensors and transducers detect physical or electrical phenomena (e.g., voltage, current, sound, fluid flow, gas pressure, force, temperature, light intensity).

- Signal Conditioning: Signal conditioners amplify, filter, and isolate the sensor signals, preparing them for digitization. This ensures high accuracy and noise immunity.

- Analog-to-Digital Conversion (ADC): Analog signals are sampled and converted into digital values by high-precision ADCs.

- Data Input and Processing: Digital data streams into a computer or embedded processor, where it is managed, visualized, and archived using specialized data acquisition software.

Data Acquisition Software Programs

Programming languages and development environments for DAQ systems play a critical role in application flexibility, performance, and ease of use:

- LabVIEW: The industry-leading graphical programming environment for rapid DAQ development and intuitive visualization.

- C/C++: Offers direct hardware access, performance optimization, and integration with real-time systems.

- Python: Increasingly used for test automation, data processing, and scripting due to its extensive scientific libraries.

- MATLAB: Popular in engineering, scientific analysis, and algorithm development, with native support for instrument control.

- Java: Noted for platform independence and cross-system compatibility.

- Pascal, BASIC, Lisp: Still used in legacy systems, rapid prototyping, or educational settings.

The optimal programming environment depends on application complexity, hardware requirements, existing infrastructure, and team expertise.

Are you comparing DAQ software packages or deciding between LabVIEW and MATLAB for your project?

Search our Data Acquisition Software guide or ask, “Which programming language is best for my data acquisition system?”

Types

Data acquisition systems come in several architectures, each optimized for specific applications, integration needs, and scalability. Understanding these types is essential for selecting a DAQ system that matches your operational, technical, and budgetary requirements.

Major DAQ System Types:

- PC-Based Data Acquisition Systems: These systems leverage desktop or industrial computers as host controllers, supporting high-channel-count, high-speed, and multi-parameter acquisition. They are ideal for laboratory research, industrial automation, and applications needing advanced data processing or visualization.

- USB Data Acquisition Systems: These plug-and-play devices offer portable, flexible data collection. USB DAQ modules are popular for field work, educational labs, and mobile testing, supporting hot-swapping and easy expansion.

- SCADA Systems (Supervisory Control and Data Acquisition): SCADA platforms integrate DAQ hardware and software for large-scale, distributed process monitoring and automation. They support real-time remote control, alarm management, and data logging across multiple sites. SCADA is standard in utilities, energy, water treatment, and manufacturing.

- Embedded and Distributed DAQ Systems: Designed for integration within machinery or remote installations, these systems deliver real-time, standalone data acquisition with onboard processing and local storage. Wireless DAQ modules enable IoT and IIoT deployments.

Looking for a DAQ solution for field data logging, SCADA integration, or portable diagnostics?

Search “best USB data acquisition modules,” “embedded DAQ for remote monitoring,” or “SCADA-compatible DAQ systems” for targeted advice and product comparisons.

Equipment Components

A reliable data acquisition setup relies on high-quality components that ensure accurate, noise-free, and scalable operation. Core DAQ system elements include:

- Sensors/Transducers: Convert physical events (temperature, force, flow, vibration, pressure, etc.) into electrical signals. The choice of sensor is critical for accuracy, range, and environmental compatibility.

- Signal Conditioning Modules: Amplify, filter, and isolate sensor signals. They enable compatibility with ADCs, protect against electrical interference, and enhance measurement fidelity.

- Analog-to-Digital Converters (ADCs): Digitize the conditioned signals with high resolution (measured in bits) and sampling rates (Hz, kHz, MHz).

- Data Acquisition Cards/Modules: Interface between field signals and computers. Modern DAQ cards integrate ADCs, digital I/O, timers, multiplexers, and onboard memory for high-speed, synchronized data capture.

- Data Loggers and Recorders: Standalone or PC-connected devices for long-term, unattended data storage. Often used in environmental monitoring, industrial audits, and regulatory compliance.

- Temperature Recorders: Specialized loggers for HVAC, meteorology, laboratory testing, and cold chain monitoring.

- Remote Terminal Units (RTUs): Microprocessor-based devices for remote SCADA integration, telemetry, and distributed control.

Additional accessories: Multiplexers, relays, power supplies, wireless gateways, and rugged enclosures extend DAQ system capabilities for harsh or remote environments.

Need help choosing sensors or DAQ modules for your specific application? Search for “recommended sensors for vibration monitoring,” “high-speed ADCs for automotive testing,” or “wireless data loggers for environmental monitoring.”

Benefits

Investing in a robust data acquisition system delivers a host of benefits that enhance operational efficiency, product quality, regulatory compliance, and business intelligence. Key advantages include:

- Real-Time Data Collection and Monitoring: Instant access to critical process variables enables immediate troubleshooting, rapid decision-making, and process optimization.

- High-Speed and High-Volume Data Capture: Essential for tracking fast-changing events, ensuring no critical data is lost in dynamic environments (e.g., crash testing, high-speed manufacturing).

- Data Accuracy and Integrity: Advanced DAQ systems provide low-noise, high-resolution measurements, essential for scientific research, medical diagnostics, and industrial quality control.

- Scalability and Flexibility: Modular DAQ architectures grow with your needs—add channels, integrate new sensors, or expand geographically with distributed systems.

- Broad Sensor Compatibility: Support a wide range of physical phenomena and sensor types, from thermocouples and strain gauges to photodiodes and accelerometers.

- Regulatory Compliance and Traceability: Automated data logging and secure storage aid in meeting standards such as ISO 9001, FDA 21 CFR Part 11, and others.

- Data Visualization and Analytics: DAQ software enables real-time dashboards, trend analysis, and predictive maintenance insights.

- Cost Reduction: By automating data acquisition, organizations reduce labor costs, minimize downtime, and prevent expensive process failures.

Curious how a modern DAQ system can transform your operation? Search “benefits of data acquisition in manufacturing,” “DAQ for regulatory compliance,” or “ROI of automated data logging.”

Design Customization

Custom data acquisition systems are tailored to meet unique requirements—whether for specialized research, industrial automation, or mission-critical applications. Key design customization factors:

- Requirements Gathering: Define the types of data, sampling rates, environmental conditions, and analysis needs. Engage stakeholders to establish user interface, reporting, and compliance requirements.

- Hardware Selection: Choose sensors, signal conditioners, and ADCs compatible with your measurement range, accuracy, and speed. Consider modularity for future expansion.

- Communication Interfaces: Select data transfer protocols (USB, Ethernet, WiFi, CAN, MODBUS, OPC-UA) that integrate with your existing infrastructure and IT security requirements.

- Software Environment: Match programming language and development tools (LabVIEW, Python, C++, MATLAB) to your team’s expertise and application complexity.

- Scalability and Modular Design: Build for future growth—ensure new sensors, channels, or locations can be added with minimal disruption.

- User Experience (UX): Develop intuitive dashboards, alarms, and analytics tools. Emphasize usability, visualization, and automated reporting for non-technical users.

- Testing and Validation: Rigorously test for accuracy, repeatability, and compliance. Incorporate feedback cycles to refine system features and performance.

Wondering how to design a custom DAQ system for your lab or factory? Search “custom DAQ system design process,” “best practices for scalable data acquisition,” or “integrating DAQ with SCADA and MES.”

Safety and Compliance Standards and Organizations

Data acquisition systems must comply with a variety of standards to ensure safety, accuracy, and interoperability. Key standards, regulations, and organizations include:

- National Instruments (NI) DAQ Hardware Compliance: Ensures products meet electrical safety, EMC, and environmental benchmarks.

- National Electrical Code (NEC): Governs wiring, grounding, and installation practices to mitigate electrical hazards in DAQ deployments.

- Occupational Safety and Health Administration (OSHA): Requires DAQ systems used in workplaces to meet safety guidelines, particularly for hazardous environments.

- International Electrotechnical Commission (IEC) Standards: IEC 61010 (electrical safety), IEC 61326 (EMC), and IEC 60068 (environmental testing) are widely adopted for global compliance.

- Food and Drug Administration (FDA) Regulations: For medical and pharmaceutical DAQ systems, compliance with FDA data integrity, privacy, and security is mandatory.

- ANSI (American National Standards Institute): Coordinates voluntary consensus standards, ensuring compatibility and safety in DAQ systems.

- IEEE (Institute of Electrical and Electronics Engineers): Develops technical standards for DAQ protocols, interfaces, and interoperability (e.g., IEEE 1451 for smart transducers).

Compliance guarantees data reliability, safety, and market access. Regularly verify: Certification status (e.g., ISO 9001, AS9100), software validation, and adherence to cybersecurity best practices for networked DAQ systems.

Looking for DAQ systems that meet industry-specific standards? Search “FDA-compliant DAQ for medical devices,” “IEC 61010 certified data acquisition systems,” or “AS9100 DAQ solutions for aerospace.”

How to Choose the Right Data Acquisition Systems Manufacturer

Selecting the best data acquisition system manufacturer is critical for ensuring your project’s success—whether for industrial automation, scientific research, or automotive testing. Platforms like IQS Directory offer comprehensive listings and tools to compare DAQ suppliers based on technical expertise, product offerings, and support services. Here’s a step-by-step guide to making an informed decision:

- Define Your DAQ System Requirements

- Identify measurement parameters: temperature, pressure, voltage, current, vibration, etc.

- Clarify application: industry (e.g., automotive, aerospace, environmental, medical).

- Determine channel count, sampling rate, and required accuracy.

- Assess environmental conditions: lab, field, or harsh industrial settings.

- Plan for integration: connectivity (USB, Ethernet, WiFi, CAN, Modbus), compatibility with SCADA/MES/ERP.

- Set budget, scalability, and future expansion goals.

- Navigate Listings on IQS Directory

- Use the search bar: Try phrases like “data acquisition systems,” “industrial DAQ suppliers,” or “USB DAQ modules.”

- Browse by category or state: Useful for local sourcing (e.g., Texas, Michigan, Rhode Island).

- Explore related supplier pages: “Data Loggers,” “DAQ Software,” or “Process Control Systems.”

- Filter Manufacturers Based on Key Criteria

- Proximity for faster delivery/support

- System features: modularity, ruggedness, connectivity, software support

- Industry/application focus: aerospace, automotive, medical, energy, etc.

- Certifications and compliance: AS9100 (aerospace), ISO 17025 (calibration), FDA, IEC/ANSI/IEEE standards

- Technical support and aftersales services

- Evaluate Manufacturer Profiles

- Product portfolio: Does the supplier offer the DAQ type you require?

- Experience: Years in business, relevant case studies, client testimonials

- Customization: Ability to tailor solutions for your specific use case

- Support: Pre-sales consultation, technical documentation, integration assistance

- Contact for Quotes and Details

- Use RFQ forms to specify your needs (channel count, environment, protocols, software requirements)

- Ask about standards compliance, software compatibility, calibration, and support contracts

- Request references or case studies from similar industries

- Research Beyond IQS Directory

- Visit manufacturer websites for product specs and whitepapers

- Check independent reviews and user forums for reliability and support feedback

- Validate certifications (e.g., AS9100, ISO 17025) and industry experience

- Compare multiple suppliers for best value, quality, and support

- Evaluate Long-Term Support and Scalability

- Ensure ongoing technical support and regular software updates

- Confirm system scalability for future channel expansion or integration with emerging technologies (IoT, cloud analytics)

- Check warranty terms, calibration services, and upgrade paths

Still have questions? Ask, “Which DAQ manufacturer is best for automotive test labs?” or “How do I compare modular vs. portable DAQ solutions?” Or explore our extended supplier listings for in-depth profiles.

Decision Factors for Buyers:

- Performance: Can the DAQ system meet your speed, accuracy, and reliability needs?

- Integration: Will it connect easily with your existing hardware, software, and networks?

- Support: Is technical assistance available during setup and operation?

- Compliance: Does the system meet regulatory and industry-specific standards?

- Total Cost of Ownership: Factor in installation, maintenance, calibration, and upgrade costs.

By following this process and leveraging trusted platforms like IQS Directory, you can confidently select a data acquisition system manufacturer that aligns with your operational goals, technical requirements, and industry standards—ensuring long-term success and ROI.

For more insights, search “how to choose a DAQ supplier,” “best practices for DAQ procurement,” or “top-rated DAQ system manufacturers for industrial automation.”

What are the primary applications of data acquisition systems?

Data acquisition systems are widely used in industries such as aerospace and defense, medical and life sciences, environmental monitoring, industrial manufacturing, automotive testing, and more. They enable accurate measurement, monitoring, and process control by converting analog sensor signals into digital data for real-time analysis and automation.

How does a data acquisition system work?

A data acquisition system collects signals from sensors, conditions them (amplifies, filters, and isolates), converts the analog signals to digital using an analog-to-digital converter (ADC), and processes the data in a computer or embedded device using specialized software for visualization, analysis, and storage.

What are the main types of data acquisition systems?

Major types include PC-based data acquisition systems, USB data acquisition systems, SCADA systems for large-scale monitoring, and embedded/distributed DAQ systems with local processing and wireless capabilities. Choice depends on application needs, scale, and integration requirements.

What are the essential components of a data acquisition system?

Core components include sensors/transducers to capture signals, signal conditioning modules, analog-to-digital converters (ADCs), data acquisition cards or modules, data loggers or recorders, and remote terminal units (RTUs) for remote applications. Accessories such as multiplexers and enclosures enhance system performance and reliability.

What are the key benefits of using a data acquisition system?

Benefits include real-time data collection, high-speed and high-volume data capture, improved accuracy and integrity, scalability, compatibility with various sensors, support for regulatory compliance, enhanced data visualization and analytics, and cost reductions through automation and reduced downtime.

Which safety and compliance standards apply to data acquisition systems?

Relevant standards and organizations include National Instruments DAQ hardware compliance, National Electrical Code (NEC), OSHA, IEC (such as IEC 61010, IEC 61326), FDA regulations for medical devices, ANSI, and IEEE (e.g., IEEE 1451 for smart transducers). Compliance ensures safety, reliability, and market access.

How do I choose the right data acquisition system manufacturer?

Start by defining your technical and application requirements, review manufacturers on platforms like IQS Directory, compare vendors based on experience, product portfolio, certifications, and support, and ensure the system matches your scalability, compliance, and integration needs before purchase.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services