Data acquisition software transfers collected data to a file or database. The collected data can be measured, analyzed, or presented on an interface. Data acquisition software helps people store, process, and organize data. Data acquisition software (DAQ software) can be destined with multiple programming languages. Read More…

CAS DataLoggers is a B-2-B distributor of data loggers and data acquisition systems required by industries in need of data collection, monitoring and control of environmental, production, process and quality control variables. From more than 18 manufacturers, we offer high-speed, high-accuracy data acquisition systems that can record temperature, force/strain, flow, voltage, vibration and more....

At Oil-Air Products, we are dedicated to delivering advanced hydraulic and pneumatic solutions that help our customers achieve greater control, efficiency, and performance in their systems. A key part of that mission is our expertise in Data Acquisition Systems, which allow us to capture, monitor, and analyze critical information from fluid power applications.

When it comes to data acquisition and control for the distribution and manufacturing industries, we can help. We are systems integrators who understand data acquisition software and data recorder functions-inventory control (raw material, finished goods), tracking (print job, work order, tool room) and more.

More Data Acquisition Software Manufacturers

Most businesses purchase DAQ software to set up without the hassle of development and installation. Purchasing a DAQ system is more affordable than maintaining a home-grown data-collecting software package. Consequently, many businesses purchase DAQ software and adjust it to their needs.

A DAQ system consists of a computer, measurement equipment, and sensors. Only some applications require a DAQ system. Manufacturers should consider using one when collecting data on electrical or physical phenomena. When DAQ systems detect and display measurements, technicians can easily locate and eliminate potential issues. DAQ software optimizes manufacturing processes and enables quicker reactions to potential faults.

Data collection can be a complicated procedure. Human error during input, credit control, system integration, and auditing can cause issues. Databases may need to be updated for accuracy. It takes effort to prepare data in an accessible format. There are numerous feed formats to manage, including flat files and comma-separated values (CSV). One of the main problems is that outside field employees need to comprehend the system you set up. If they don’t, collected data may be erroneous or lost.

What is a Data Acquisition System (DAQ)?

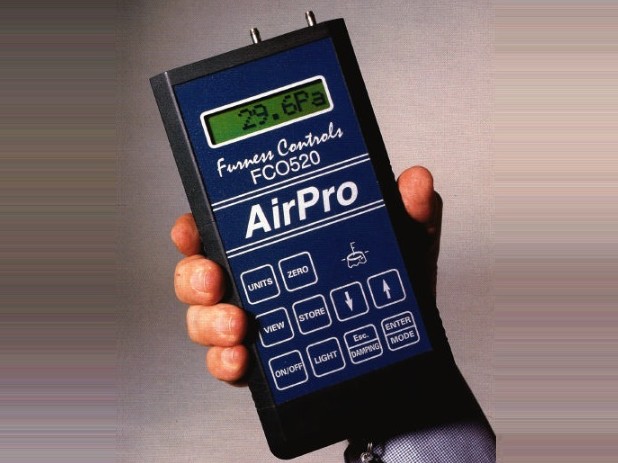

A data acquisition system (DAQ) is a combination of hardware and software that collects, measures, and analyzes physical or electrical signals from real-world environments. These systems are critical in industrial automation, research, product testing, and process control. DAQ solutions provide a reliable method for capturing sensor data, monitoring operational performance, and supporting predictive maintenance strategies. By utilizing advanced DAQ hardware and intuitive data acquisition software, engineers and technicians can gain actionable insights to optimize manufacturing workflows, improve product quality, and ensure regulatory compliance.

Components of a Data Acquisition System

Every robust data acquisition system is built around several core components, each playing a vital role in accurate data measurement and analysis. Understanding how these components work together is key for anyone evaluating DAQ systems for industrial automation, laboratory research, environmental monitoring, or process engineering.

- Analog-to-Digital Converter (ADC): The foundation of every data-gathering system, the ADC transforms analog signals, such as voltage or current, into multilevel digital signals that PCs and DAQ software can process. The electronic analog-to-digital conversion process quantifies signals into binary-coded formats, enabling digital storage, display, and advanced analytics.

- Measurement Sensors: Sensors convert physical phenomena—such as temperature, pressure, vibration, flow, or force—into electrical signals compatible with DAQ hardware. Proper sensor selection ensures high accuracy and repeatability in measurement data.

- Signal Conditioning: Signal conditioners amplify, filter, and convert raw sensor signals to match the input requirements of DAQ systems. They ensure compatibility, boost signal quality, and minimize electrical noise. For example, signal conditioning for strain gauges often involves excitation, bridge completion, and calibration circuits. Many MEMS (micro-electro-mechanical systems) sensors also incorporate signal conditioning functions.

- Data Acquisition Hardware: This includes input/output modules, analog and digital interfaces, and communication cards. DAQ hardware links sensors and computers, often providing real-time data streaming, signal multiplexing, and system synchronization.

- DAQ Software: User-friendly data acquisition software is essential for configuring measurement channels, logging data, triggering events, real-time visualization, and exporting results. Advanced DAQ platforms support remote monitoring, automated analysis, and integration with enterprise databases or cloud storage.

- Computers and Networking: Modern DAQ systems often leverage industrial PCs, embedded controllers, or edge computing devices for robust, scalable data processing. Networking capabilities enable remote access, system integration, and IoT data aggregation.

Analog input can vary. For example, analog input might be human speech or television signals that form sine waves. The ADC process converts the sine waves into a digital signal. The digital signal is easier to measure and analyze.

Signal Conditioning in Data Acquisition Systems

A signal conditioner transforms an electrical or mechanical signal into an output signal. During this process, the signal is amplified and converted to be compatible with data-collecting software. Signal conditioners help capture precise measurements.

Signal conditioners are multi-faceted gadgets because they must work with various sensors. Different sensors demand different signal processing techniques. For example, signal conditioning for a strain gauge requires stimulation, bridge completion, and calibration.

Circuitry for signal conditioning can be found in a data acquisition system or a transducer. For instance, bridge completion, calibration, and amplification circuits are present in load cells. Many MEM (micro-electro-mechanical) sensors also incorporate signal conditioning.

Why Is Signal Conditioning Important?

Proper signal conditioning is vital for minimizing measurement errors and ensuring high-fidelity data. In environments with electrical interference or long cable runs, signal conditioners filter out noise, isolate sensitive signals, and prevent ground loops. This is especially important in industrial automation, automotive testing, aerospace, and R&D applications, where precise and reliable measurements drive decision-making and product development.

What Variables Can Data Acquisition Software Measure?

DAQ software measures variables like current, voltage, frequency, pressure, temperature, distance, vibration, angles, digital signals, and weight. For example, SCADA is a DAQ system, short for Supervisory Control And Data Acquisition. SCADA systems specifically collect live data from a remote location. SCADA is often used to monitor voltage or pressure levels in various contexts.

- Temperature: Using thermocouples, RTDs, or thermistors, DAQ systems accurately log temperature changes in industrial equipment, environmental chambers, or scientific experiments.

- Pressure: Critical for process industries, DAQ software tracks fluid and gas pressures using compatible transducers and digital interfaces.

- Vibration & Acceleration: Essential in predictive maintenance, DAQ systems can analyze vibration spectra to detect bearing faults, machinery imbalances, or structural weaknesses.

- Electrical Signals (Voltage, Current, Resistance): Measure and record electrical parameters for power systems, battery testing, or electronic product validation.

- Force, Load, and Weight: Used in materials testing, quality assurance, and industrial weighing applications.

- Frequency and Pulse: Capture timing and frequency data for rotating equipment, motor control, or flow measurement.

- Digital Inputs/Outputs: DAQ platforms monitor machine status, process events, or control actuators in real time.

Industry Applications of DAQ Systems

Looking for data acquisition solutions tailored to your industry? DAQ systems are widely used in:

- Industrial Automation: Monitor and control factory processes, ensure quality, and enable real-time diagnostics.

- Automotive Testing: Capture vehicle performance, emissions, and safety parameters during development and validation.

- Environmental Monitoring: Track weather conditions, air quality, water quality, and pollution levels using remote DAQ and IoT connectivity.

- Energy & Utilities: Analyze power generation, distribution, and consumption in renewable and conventional energy sectors.

- Aerospace & Defense: Support flight testing, structural analysis, and mission-critical data logging.

- Scientific Research: Facilitate reproducible experiments, data integrity, and statistical analysis for laboratories.

- Medical & Life Sciences: Record physiological signals, support device development, and ensure compliance with regulatory standards.

Desired Qualities of Data Acquisition Software

- It’s beneficial to have user-friendly DAQ software that is easy to modify. The more intuitive the software, the less likely end users will create erroneous data.

- A good DAQ platform should be capable of basic functions like logging, alerts, and control. However, DAQ software should also be flexible enough to configure for other functions.

- For easy integration, DAQ software should be built with standardized programming languages for developers.

- Scalability: As your data needs grow, your DAQ software should support additional input channels, distributed devices, or cloud connectivity without major rework.

- Real-Time Monitoring and Visualization: Live dashboards, trend charts, and customizable alerts keep your team informed and responsive.

- Data Security and Compliance: Robust security features, audit trails, and regulatory compliance (such as FDA 21 CFR Part 11) are essential in high-stakes industries.

- Interoperability: Seamless integration with MES, ERP, PLCs, and legacy systems streamlines workflows and centralizes data management.

- Remote Access and IIoT Readiness: Modern DAQ solutions should offer secure remote access, web-based interfaces, and support for IIoT protocols like MQTT or OPC-UA.

How to Evaluate DAQ Software Vendors

When researching DAQ software providers, consider these key questions to match your application requirements:

- Does the software support your required sensor types and communication protocols?

- Is the user interface intuitive for both engineers and non-technical staff?

- Can the platform handle data rates and volumes typical for your process or experiment?

- Is there robust technical support, documentation, and community resources?

- How easy is it to integrate the DAQ system with your existing ERP, MES, or cloud storage?

- Are there options for custom scripting, automation, or API integrations?

- What are the licensing, maintenance, and upgrade policies?

Ready to compare leading DAQ software solutions? Browse our DAQ software manufacturers directory to find the best fit for your project.

Benefits of Using Data Acquisition Systems

- DAQ systems are incredibly accurate.

- DAQ software helps technicians anticipate problems in a manufacturing system.

- Increased Productivity: Automated data collection eliminates manual entry, reduces human error, and accelerates decision-making.

- Cost Savings: Early fault detection and predictive maintenance minimize unplanned downtime, protecting revenue and reducing repair costs.

- Regulatory Compliance: DAQ systems provide traceable, auditable records necessary for industry certifications and legal requirements.

- Scalable Data Management: Store, analyze, and visualize large datasets for long-term trend analysis and process optimization.

- Enhanced Product Quality: Real-time feedback enables immediate process adjustments, ensuring consistent quality and reducing scrap.

- Remote Monitoring: IIoT-enabled DAQ systems allow for secure, web-based monitoring and control from anywhere in the world.

Common Use Cases and Applications for DAQ Systems

- Condition Monitoring: Track asset health in real time to predict failures and extend equipment lifespan.

- Laboratory Automation: Streamline data collection and experiment control for high-throughput research environments.

- Product Development & Testing: Measure and validate prototype performance, ensuring products meet specifications and safety standards.

- Process Optimization: Analyze production data to identify bottlenecks, improve efficiency, and reduce waste.

- Remote Environmental Sensing: Deploy DAQ systems for continuous field data collection in agriculture, meteorology, or infrastructure monitoring.

- Energy Management: Monitor energy consumption, power quality, and grid performance in smart factories or utility operations.

Frequently Asked Questions About DAQ

- What is the difference between DAQ and SCADA? While both collect and monitor data, SCADA focuses on supervisory control, automation, and remote operations, whereas DAQ emphasizes data measurement, logging, and analysis.

- How do I choose the right DAQ system? Consider channel count, sampling rate, sensor compatibility, software features, scalability, and support for required protocols.

- Can DAQ systems be integrated with cloud platforms? Yes, many modern DAQ solutions offer built-in cloud connectivity for remote monitoring, big data analytics, and IIoT applications.

- Is calibration necessary for DAQ systems? Regular calibration ensures measurement accuracy and compliance with quality standards.

Choosing the Correct Wire Storage Racks Manufacturer

To make sure you have the most positive outcome when purchasing Wire Storage Racks from a Wire Storage Racks Manufacturer, it is important to compare at least 4 Companies using our Wire Storage Racks directory. Each Wire Storage Racks Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Wire Storage Racks company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Wire Storage Racks companies with the same message.

Get Started with Data Acquisition Solutions

Are you ready to upgrade your data collection processes or modernize your testing and measurement operations? Explore our curated list of DAQ software and hardware manufacturers to find the best-fit solution for your unique requirements. Whether you’re searching for turn-key DAQ systems, modular data loggers, high-speed data acquisition hardware, or customized integration services, our directory connects you with industry leaders who can help you achieve your goals.

Still have questions or want to learn more? What type of DAQ system is best for your application? Contact our experts for personalized recommendations, or use our advanced search features to filter DAQ solutions by industry, capabilities, and certification.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services