A digital data recorder measures, records, and displays input signals. Digital data recorders make it simple to compare complex information using user interface displays. Data recorders measure attributes like temperature, flow, pressure, mass, energy, voltage, current, and resistance. After being recorded, the data is often saved or backed up on a computer. Read More…

CAS DataLoggers is a B-2-B distributor of data loggers and data acquisition systems required by industries in need of data collection, monitoring and control of environmental, production, process and quality control variables. From more than 18 manufacturers, we offer high-speed, high-accuracy data acquisition systems that can record temperature, force/strain, flow, voltage, vibration and more....

At Oil-Air Products, we are dedicated to delivering advanced hydraulic and pneumatic solutions that help our customers achieve greater control, efficiency, and performance in their systems. A key part of that mission is our expertise in Data Acquisition Systems, which allow us to capture, monitor, and analyze critical information from fluid power applications.

When it comes to data acquisition and control for the distribution and manufacturing industries, we can help. We are systems integrators who understand data acquisition software and data recorder functions-inventory control (raw material, finished goods), tracking (print job, work order, tool room) and more.

More Data Recorder Manufacturers

Types of Data Loggers

Digital recorders can capture and store waveform data. A data recorder is continuously recording, so it’s more likely to catch trigger events, and offers more channels, memory, and higher vertical resolution. To ensure that important data is recovered, precision recorders offer a pre-trigger option that lets one choose a percentage of time to capture before the trigger occurrence.

Voltage, resistance, and current are the three main variables that digital multimeters (DMM) are used to measure. Data recorders can measure the same factors, but they can additionally track temperature, humidity, vibration, strain, and rotation. The data can be uploaded to a computer or evaluated on-screen. Data recorders can develop equations for mathematical computations between two or more channels.

Similar triggering mechanisms to those found on scopes are frequently found in data recorders, such as triggers based on the rising and falling edges of the signal being recorded. It’s simple to find recorders that offer the same analysis seen on specialized equipment like power line quality monitors. Data recorders also offer features like X-Y displays, which have traditionally been found on oscilloscopes.

Application of Data recorders

Data recorders are often used in environmental testing. At a weather station, data recorders will track variables like temperature, humidity, wind speed, direction, and barometric pressure. These environmental tests may also happen in an environmental chamber to check how the device responds to environmental factors while monitoring voltage and current.

The automotive industry also makes extensive use of data recorders. The gadget can simultaneously monitor the multiple sensors, electrical controllers, and systems used in motor vehicles. A data recorder can track voltage, current, force, pressure, stress/strain, speed, and temperature.

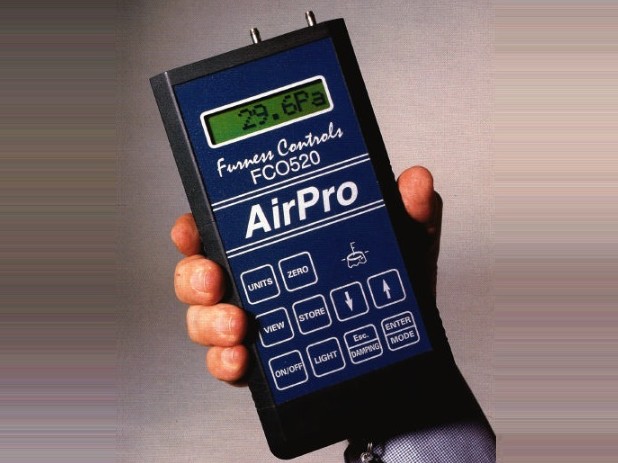

In a commercial environment, portable recorders can optimize productivity using preventative maintenance procedures. They can monitor equipment's strain, detect anomalies, and store information to facilitate preventative maintenance.

What to Consider When Choosing Data Recorders

When choosing a data recorder, manufacturers should consider the number of input channels, measurement capabilities, minimum and maximum voltage, sampling rate, and memory capacity. Portability may have to be sacrificed for more input channels - a data recorder gets heavier with more input channels.

Be attentive when considering a data recorder’s sampling rate and memory size. It is crucial to know which signals will be recorded. A quicker sampling rate may seem advantageous. However, a quick sampling rate with a fixed memory size will shorten the recording time. Some data recorders can synchronize other systems, such as GPS signals.

Advantages of data recorders

- Data recorders offer a dependable, affordable, and time-effective monitoring solution. Data recorders are precise, intuitive, and versatile.

- A data recorder minimizes human error, recording measurements in a timely fashion.

- Data logging equipment can go to dangerous environments where humans can’t, like Mars or a volcano crater.

- The data logging program can automatically generate graphs, tables, and visual interpretations of results.

Choosing the Correct Data Recoders Company

To make sure you have the most constructive outcome when purchasing Data Recoders from a Data Recoders Company, it is important to compare at least 4 or 5 Companies using our list of Data Recoders companies. Each Data Recoders Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Data Recoders business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Data Recoders businesses with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services